yngwie308

Fender Strat Neck Mounting-Slight Return

Moderators: VelvetGeorge, BUG

- yngwie308

- Senior Member

- Posts: 4623

- Joined: Tue May 23, 2006 11:21 pm

- Location: Valhalla, Arizona

Fender Strat Neck Mounting-Slight Return

Here we can continue our discussion from the Hendrix artistes section, as this is the more appropriate section

yngwie308

yngwie308

http://www.vintagewashburn.com/Electric ... evens.html" onclick="window.open(this.href);return false;

http://www.treblebooster.net/bolin.html" onclick="window.open(this.href);return false;

http://www.treblebooster.net/bolin.html" onclick="window.open(this.href);return false;

- fillmore nyc

- Senior Member

- Posts: 3193

- Joined: Wed May 09, 2007 8:59 am

- Just the numbers in order: 7

So, getting back to the neck mounting issue, do you think there is a possibility of ripping the brass inserts out of the neck if the bolts are somewhat overtightened? (I KNOW... they shouldnt be made too tight, but thats what we (I ?) do).

Like I said in the Hendrix thread, I've always wanted to do this mod, but having somewhat of an engineers view on things, I have this thought in my head that the only thing stopping them from getting torn out is the wood in the neck itself, and the "resistance" of the body wood in the neck pocket.

I have this vision of the brass inserts being pulled out of the neck, and burrowing their little brass asses into the body wood. Any validity to this, or is paranoia showing up to work in my shop for the day... again???

/

/

/

/

Like I said in the Hendrix thread, I've always wanted to do this mod, but having somewhat of an engineers view on things, I have this thought in my head that the only thing stopping them from getting torn out is the wood in the neck itself, and the "resistance" of the body wood in the neck pocket.

I have this vision of the brass inserts being pulled out of the neck, and burrowing their little brass asses into the body wood. Any validity to this, or is paranoia showing up to work in my shop for the day... again???

- yngwie308

- Senior Member

- Posts: 4623

- Joined: Tue May 23, 2006 11:21 pm

- Location: Valhalla, Arizona

Fill, I wouldn't worry too much about this. These brass inserts have been fitted on the MIJ YJM Strat's for many years, it depends how the insert is fitted into the neck heel.

Usually it would be a slightly undersized hole, with the brass insert being an interference fit. I would ask Fender or a competent Luthier about it.

To my mind, the machine threaded screws once the head meets the plate would make a good mechanical fit and the possibility of over torquing the screws wouldn't be an issue as long as the inserts are fitted snugly.

Whereas a spiral threaded wood screw would have the propensity to be over tightened.

I will find more out about this. I know Yngwie used to throw his guitars sometimes 15 or more feet in the air and catch them, toss them offstage to his tech, ect and they all held up well, in fact the body would split before the neck would come off with this type of neck fitment.

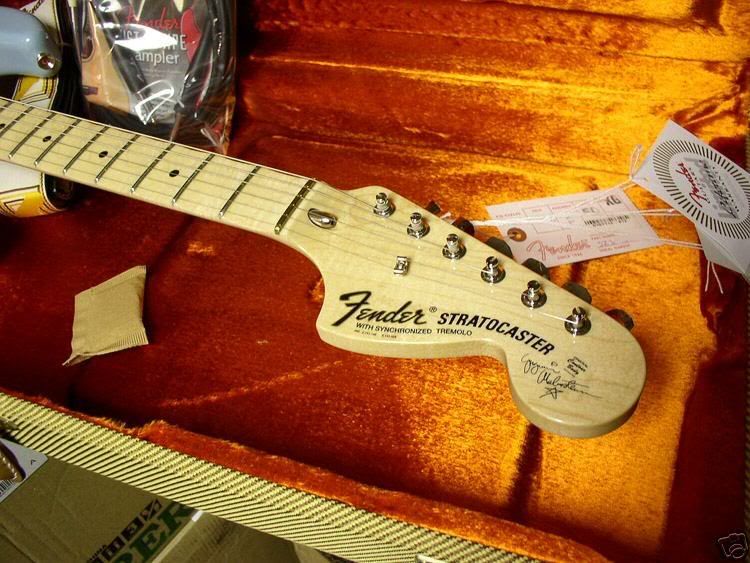

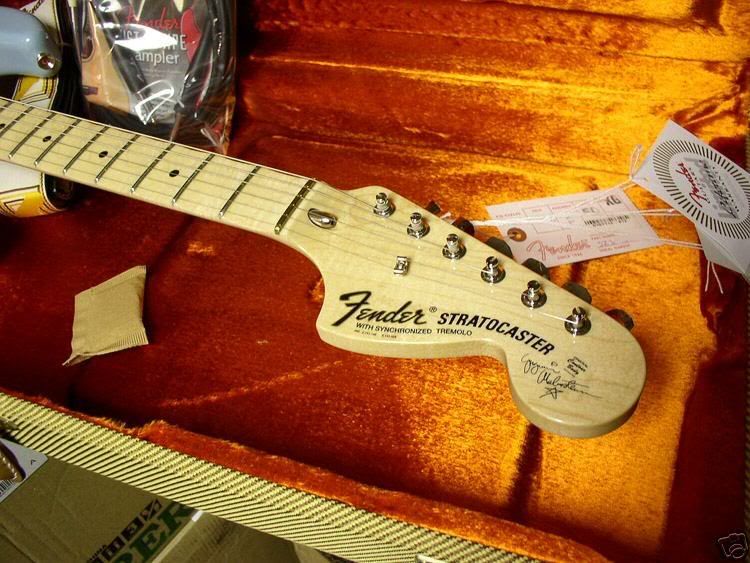

Notice that the brassinserts are slightly countersunk into the neck heel, these pics are MIJ's, so the YJM USA 2007, I would have to ask some of the guys on the YJM forum about their '07's and how they look.

Check out one of the new YJM's if you can, with the bullet truss rod and 4 bolt necks

One of the mega rare Fender Woodstock clones, 1 of 3:

yngwie308

Usually it would be a slightly undersized hole, with the brass insert being an interference fit. I would ask Fender or a competent Luthier about it.

To my mind, the machine threaded screws once the head meets the plate would make a good mechanical fit and the possibility of over torquing the screws wouldn't be an issue as long as the inserts are fitted snugly.

Whereas a spiral threaded wood screw would have the propensity to be over tightened.

I will find more out about this. I know Yngwie used to throw his guitars sometimes 15 or more feet in the air and catch them, toss them offstage to his tech, ect and they all held up well, in fact the body would split before the neck would come off with this type of neck fitment.

Notice that the brassinserts are slightly countersunk into the neck heel, these pics are MIJ's, so the YJM USA 2007, I would have to ask some of the guys on the YJM forum about their '07's and how they look.

Check out one of the new YJM's if you can, with the bullet truss rod and 4 bolt necks

One of the mega rare Fender Woodstock clones, 1 of 3:

yngwie308

http://www.vintagewashburn.com/Electric ... evens.html" onclick="window.open(this.href);return false;

http://www.treblebooster.net/bolin.html" onclick="window.open(this.href);return false;

http://www.treblebooster.net/bolin.html" onclick="window.open(this.href);return false;

-

wide slide

- Senior Member

- Posts: 278

- Joined: Mon Jun 05, 2006 4:19 pm

- Location: third stone from the sun

I don't use them, but they seem great.

Picture this...

the flat head of the insert, is countersunk even, to the back of the neck, With this, and the countersunk plate, tightening a bolt would be vertually impossible to pull the flat head of the insert thru the maple wood neck.

An impact driver wouldn't even pull the insert head thru the maple.

I think I'd like it!

ws

Picture this...

the flat head of the insert, is countersunk even, to the back of the neck, With this, and the countersunk plate, tightening a bolt would be vertually impossible to pull the flat head of the insert thru the maple wood neck.

An impact driver wouldn't even pull the insert head thru the maple.

I think I'd like it!

ws

SB

Vox Wah

Vox Wah

-

wide slide

- Senior Member

- Posts: 278

- Joined: Mon Jun 05, 2006 4:19 pm

- Location: third stone from the sun

Ok...

Like I said I don't use them...

I'm ahead of myself and thinking something different which would work great.

Yes Fill,

in the application, that the insert is used it could pull or looseen. but if the insert is installed correctly Before the neckboard in in place, and of course counter sunk, it would like I said be impossible to pull thru.

I think I just stumbled onto something good.

ws

Like I said I don't use them...

I'm ahead of myself and thinking something different which would work great.

Yes Fill,

in the application, that the insert is used it could pull or looseen. but if the insert is installed correctly Before the neckboard in in place, and of course counter sunk, it would like I said be impossible to pull thru.

I think I just stumbled onto something good.

ws

SB

Vox Wah

Vox Wah

-

wide slide

- Senior Member

- Posts: 278

- Joined: Mon Jun 05, 2006 4:19 pm

- Location: third stone from the sun

using the application posted,

if one used an expanding type insert similiar to an expanding anchor, where the end flares out would work better.

If someone could invent a drill bit that would be able to expand the hole in the maple at a certian depth, this would lend itself well with this application but I don't think there is such a tool.

if one used an expanding type insert similiar to an expanding anchor, where the end flares out would work better.

If someone could invent a drill bit that would be able to expand the hole in the maple at a certian depth, this would lend itself well with this application but I don't think there is such a tool.

SB

Vox Wah

Vox Wah

- NY Chief

- Wiki Editor

- Posts: 6589

- Joined: Thu Apr 28, 2005 6:02 pm

- Location: SoCal

You do could that with a boring bar on a milling machine.wide slide wrote:using the application posted,

if one used an expanding type insert similiar to an expanding anchor, where the end flares out would work better.

If someone could invent a drill bit that would be able to expand the hole in the maple at a certian depth, this would lend itself well with this application but I don't think there is such a tool.

fill, these things take a lot to pull or torque out when installed correctly. They're like helicoils or keenserts I'm sure you've used them at some time working on your bikes?

Check it out...http://www.ezlok.com/InsertsWood/hardWood.html

NY Chief 5-0, transplanted in SoCal

"Book 'em, Dan-o!"

"Book 'em, Dan-o!"

- Mynameisfritz

- Senior Member

- Posts: 345

- Joined: Thu Nov 15, 2007 9:02 am

- Location: Germany, Krauttown - in the middle of some cabbage fields

Just a quick post, I have to leave soon...

The inserts are a good idea. An expanding anchor is a good idea for a wall but not for a maple neck - maple is too hard for that and it could possibly break, especially the 2 bolts right at the end of the neck.

I think the crucial point is how the inserts fit in the neck - maybe it's worth to try some different inserts with different threads in an extra piece of maple and see which one can take the most. Like NY Chief said, normally it takes a lot to pull them out.

But there's another thing:

As I was fixing the neck on my '85 RI Strat a few years ago, I noticed that the diameter of the holes in the body was too big. The bolts only can pull the neck to the body and even if they are pulled very tight, they can't prevent the neck from moving around in the neck pocket sideways - hope you understand that improvised carpenter english ... I reduced the diameter of the holes and it improved the fitting of the neck a good deal.

Sorry, I have to leave...

The inserts are a good idea. An expanding anchor is a good idea for a wall but not for a maple neck - maple is too hard for that and it could possibly break, especially the 2 bolts right at the end of the neck.

I think the crucial point is how the inserts fit in the neck - maybe it's worth to try some different inserts with different threads in an extra piece of maple and see which one can take the most. Like NY Chief said, normally it takes a lot to pull them out.

But there's another thing:

As I was fixing the neck on my '85 RI Strat a few years ago, I noticed that the diameter of the holes in the body was too big. The bolts only can pull the neck to the body and even if they are pulled very tight, they can't prevent the neck from moving around in the neck pocket sideways - hope you understand that improvised carpenter english ... I reduced the diameter of the holes and it improved the fitting of the neck a good deal.

Sorry, I have to leave...

- fillmore nyc

- Senior Member

- Posts: 3193

- Joined: Wed May 09, 2007 8:59 am

- Just the numbers in order: 7

Well, I COULD grab my wifes cell phone and call... ummm, lessee... myself...yngwie308 wrote:I would ask Fender or a competent Luthier about it.

(just kidding... whaddoo I know about guitars...

No seriously, I understand your point with the neck anchors. I think its a great idea, and one of these days I'll pick a labratory guitar and try it. I always look to try different ideas to try improving stability in a guitar, whether thats neck, bridge, etc.

I had the idea of locking a tune-o-matic down to the guitars top YEARS before Tone Pros came out with it, but I honestly dont think it really made that much difference. I countersunk a pair of fully threaded 10-32 socket cap bolts into a tune-o-matic, rethreaded the thumbwheels to 10-32, and threaded the socket cap bolts directly into the top of a LP, and tightened the thumbwheels up to lock the bridge solidly in place. It was strong and solid as a mutha, and sounded exactly the same as a regular LP bridge.

I think a lot of these things are a "gitnip". (good in theory, not in practice), but thats how you learn, and its also how you stumble on killer ideas.

- fillmore nyc

- Senior Member

- Posts: 3193

- Joined: Wed May 09, 2007 8:59 am

- Just the numbers in order: 7

Actually, that IS possible using a high speed cutter dremel tool bit like this:wide slide wrote:using the application posted,

if one used an expanding type insert similiar to an expanding anchor, where the end flares out would work better.

If someone could invent a drill bit that would be able to expand the hole in the maple at a certian depth, this would lend itself well with this application but I don't think there is such a tool.

http://www.dremel.com/DremelCMS/Pop-ups ... 6262&tab=1

First, you'd have to determine which cutting head diameter would be applicable. If you carefully dropped the bit into your hole, with the cutting head completely "submerged" into the hole, and then routed in a circular motion, using the bit shank as a bearing surface against the hole sides, you would end up with a hole that was bigger in diameter at the bottom of the hole than it is at the entrance of the hole.

- fillmore nyc

- Senior Member

- Posts: 3193

- Joined: Wed May 09, 2007 8:59 am

- Just the numbers in order: 7

Not on my street bikes, but years ago I stripped out the sparkplug on a dirtbike I had, and used a helicoil to repair it, so I know what you mean.NY Chief wrote:fill, these things take a lot to pull or torque out when installed correctly. They're like helicoils or keenserts I'm sure you've used them at some time working on your bikes?

These days, the only thing that strips for me is Gabriella at Lace.

We like Gabriella, Chief. She beez REEL purrrty...

-

wide slide

- Senior Member

- Posts: 278

- Joined: Mon Jun 05, 2006 4:19 pm

- Location: third stone from the sun

Good Fill!

I could see that dremmal bit working at a certian depth rideing the shaft of the bit around the hole.

I like posts like these , it gets the creative juices flowing,...

but whats funny like you mention, take a few words like Strip and mix some of the words... like in the sentence above, and it can take on a XXX meaning.

I take it Gabe is Mrs. Fill?

I take it Gabe is Mrs. Fill?

but really, good post

I could see that dremmal bit working at a certian depth rideing the shaft of the bit around the hole.

I like posts like these , it gets the creative juices flowing,...

but whats funny like you mention, take a few words like Strip and mix some of the words... like in the sentence above, and it can take on a XXX meaning.

but really, good post

SB

Vox Wah

Vox Wah

- fillmore nyc

- Senior Member

- Posts: 3193

- Joined: Wed May 09, 2007 8:59 am

- Just the numbers in order: 7

Ummm, no Gabriella works at Lace, which is a "gentlemans"wide slide wrote:Good Fill!

but whats funny like you mention, take a few words like Strip and mix some of the words... like in the sentence above, and it can take on a XXX meaning.

I take it Gabe is Mrs. Fill?

However, Mrs. Fill (I like that!!) likes Gab too, which is cool on SO many levels!!

(Its pretty awesome having a wife that actually WANTS to go to these places!! She's not yer typical woman at all, which is VERY refreshing)

-

wide slide

- Senior Member

- Posts: 278

- Joined: Mon Jun 05, 2006 4:19 pm

- Location: third stone from the sun