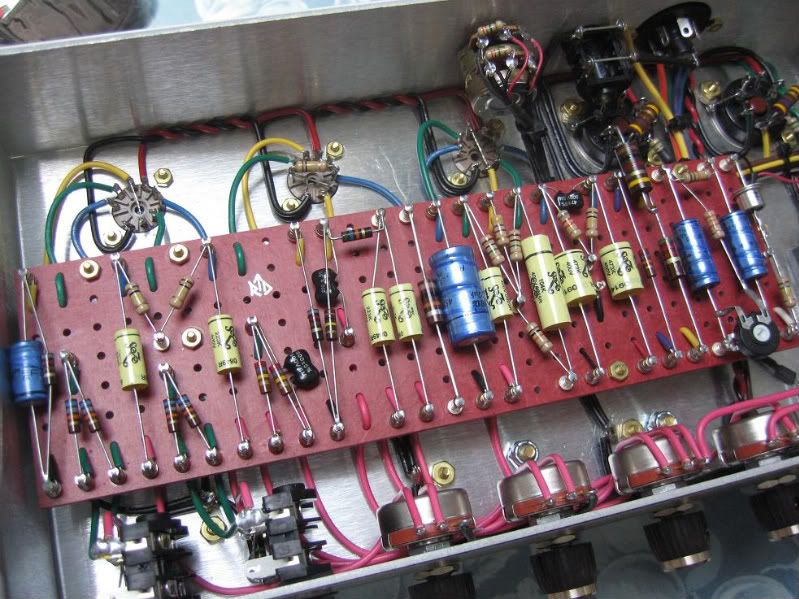

I need full-perforated boards with split turrets for a jtm50 black flag and for a jtm45. After that I will build for my wife (she plays bass for me) a 100watt super bass amp.

The original brown vintage material would be great but I think it s not available.

What is the difference between?

http://kurtsequipment.com/reproboards/" onclick="window.open(this.href);return false;

Or

http://smallbox.freeservers.com/catalog.html" onclick="window.open(this.href);return false;

Or should I drill and stack my own with the boards from metro

http://metroamp.com/store/product_info. ... cts_id=224" onclick="window.open(this.href);return false;

What is the right size for a jtm50 with a GZ34?

11 5/8 X 3 1/8 OR

12 1/2 X 3 1/8

Are those all made from GP03?

Any advice would be great

Thanks